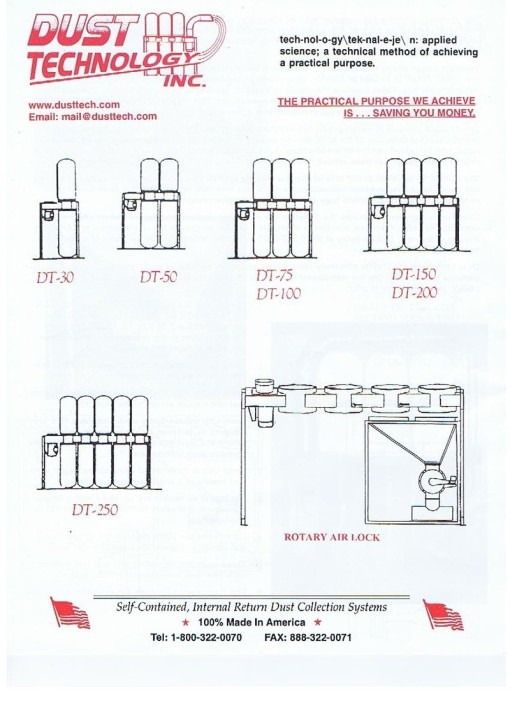

Machine Sketches

Our operation provides the customer with an affordable, efficient, low maintenance unit that also offers a very basic installation process. The application flexibility Dust Technology, Inc. provides to the customer allows for greater productivity. Greater productivity is what allows a business to remain profitable and competitive.

Compact design allows the customer to maximize factory floor space without sacrificing CFM or collection space. Waste is housed in durable, clear plastic collection bags (visit www.dustcollectionbags.com) that have a storage capacity of 15 cubic feet per bag. These bags are disposable or reusable depending on the application. The filter bags are of a special fabric designed to decrease airflow resistance. This means increased airflow, increased dust pickup and significantly lower pressure drop differentials.

Construction consists of eleven gauge, hot roll steel. Average weight of the unit is eight hundred fifty pounds, making them one of the most durable unitary collectors on the market today. An aluminum, radial type fan wheel powered by a heavy duty, T.E.F.C. motor is the driving force behind this concept. A unique latch sysem has been applied to the impeller housing to offer the customer easy access.

The feature we are most proud of is our unique baffling system. Designed to allow the customer to regulate the fill ratio in each of the collection bags. Once this even flow rate is achieved, downtime is minimized because all the collection bags can be emptied simultaneously.

Dust Technology, Inc. maintains the design to one of the industry's most efficient and reliable waste extraction systems. Our main function is to provide a proven solution to the waste control problem at a fraction of the cost. Call us today at 877-322-0070 for further information or the name of a dealer in your area.

Dust Technology, Inc. units effectively extract dust and waste material of wood, plastics, and solid surface particles produced during the manufacturing process. Please consider the following features Dust Technology, Inc. units have to offer:

- The product line consits of Models DT-30, DT-50, DT-75, DT-100, DT-150, DT-200, DT-250 and the RAL machine. Each is equipped with a 3,5,7.5,10,15, 20 and 25 HP T.E.F.C. blower motor respectively. Single phase and other voltages are available.

- Every unit is equipped with a unique baffling system that forces the colletion bags to fill evenly.

- Every unit is equipped with a unique latch system that offers quick access to the impeller.

- Every unit utilizes upper cloth filters bags that are designed to decrease airflow resistance, increase airflow and dust extraction, and significantly lower pressure drop differentials.

- Every unit is constructed using eleven-gauge steel that results in a stable, secure installation.

- The legs of all models are equipped with a height adjustment that offers flexibility from 6" to 12" in tight quarters.

- These units are 100% made in the United States and are of the highest quality.

- These units are very affordable and cost substantially less than conventional cyclone systems.

- Fire surpession systems are available, please call for information.